Singapore Aero Engine Services Private Limited are Asia’s market leader in aviation engine service and repair.

SERVICING THE BEST

Singapore Aero Engine Services Private Limited (SAESL) is a Trent Centre of Excellence, specialising in the repair and overhaul of the flourishing Rolls- Royce Trent aero engine family. The company first began operations in 2001 in Singapore, and have since serviced and repaired over 2000 engines to date, from a variety of customers including Air Transat, Singapore Airlines and Virgin Atlantic. SAESL combines the knowledge of parent company Rolls-Royce, the quintessential engine maker, with the experience of Singapore airlines Engineering Company (SIAEC).

Simon Morris, general manager of SAESL, believes that having the experience, industry knowledge and the stature of both parent companies, gives the company a solid platform to make the company the dominant force in engine servicing: “the knowledge and expertise from both Rolls Royce and SIAEC gives us flexibility to manage our engine load. we continue to grow our qualified and experienced field service support team, providing 24/7 assistance to all our customers. Additionally, we offer advanced component repair capabilities and are the recognised Rolls-Royce Centre of Excellence for compressor blade repair amongst other high technology repair processes.”

HANDLED WITH CARE

Dealing with some of the world’s biggest and most recognisable airlines is no easy feat and SAESL ensure that they are ready and equipped to deal with several different engines types. The current series of engines that the company can work on are overhaul work for Trent 500 (Airbus A340), Trent 700 (Airbus A330), Trent 800 (Boeing 777) and Trent 900 (Airbus A380) engines. “We currently work on the most widely used engines in the aviation industry including the newer Trent 900, which is the driving force behind the world’s biggest passenger plane, the A380. SAESL has also been selected to be the lead facility for the Trent XWB engine (Airbus A350 XWB), the fastest selling Trent engine ever, with more than 1,600 already on order. This is a massive boost for us, truly showcasing our market leader status,” announces Morris.

SAESL has grown quickly since it began operation, investing in the construction of their own test bed, which was completed last year and will be calibrated to test our different engine types throughout the next 18 months. This will give SAESL greater independence and help them to facilitate quick turnaround times for customers. This will in turn reduce the clients waiting time for engine repairs. “Our new engine test facility will be one of the few test facilities in the world calibrated to test the Trent XWB and this is a testament to the level that SAESL is now working at,” remarks Morris.

THE FINEST FACILITY

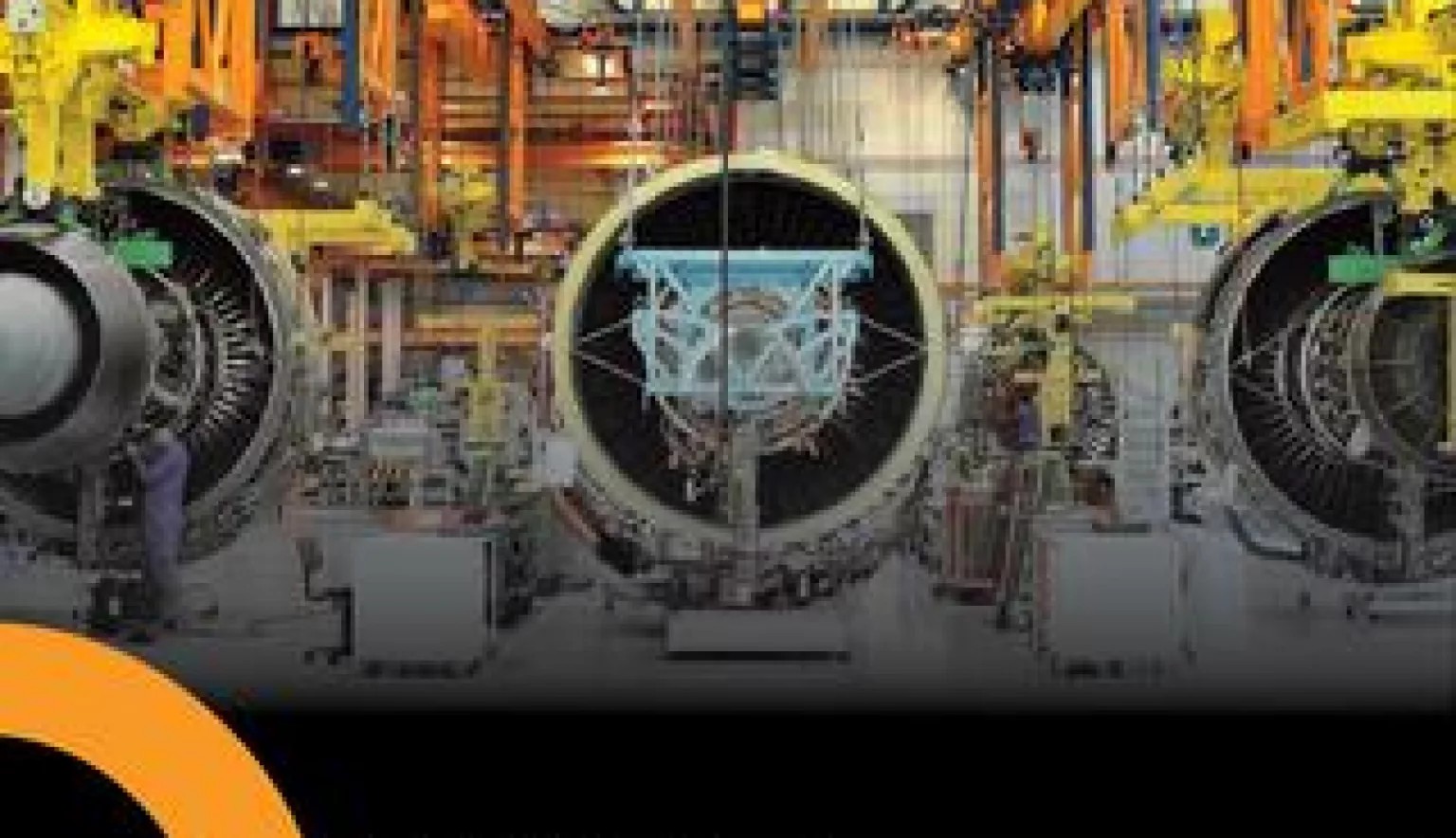

SAESL boast an impressive 30,000 square metre facility in the beating heart of Singapore’s Aerospace Industry sector. It consists of two buildings which house the main overhaul line with its state-of-the-art gantry system. The engine disassembly and assembly lines are on the ground floor. This is where SAESL’s customers’ engines arrive and are stripped to a modular level. Also housed in the main building is the modular re-work area. This is where modules are taken to once they have been removed from the engines. They are then disassembled into piece parts to be thoroughly inspected and subsequently re-assembled.

The second building making up the facility is a S$60 million investment that took SAESL’s overhaul capacity up to 250 engines a year. “This investment made in enhancing our engine capacity was a big step for us, as it allowed us to increase our portfolio of services on offer and engine repair turnover. It is integrated with the original building via a bridge to allow easy transport of parts between the two areas,” Morris explains.

The majority of this facility is occupied by the repair and rework function, where parts are sent to be refurbished before they are returned to be built into an engine. One of the foremost areas of the facility is the Centre of Excellence for compressor blades repair, the most advanced Trent engine compressor blade repair centre in the world.

ON-THE-WING REPAIRS

One of the most important parts of an aeroplane is its engine, and when a problem occurs with the engine, it can also be the most costly. Having to remove an engine and replace it with a spare can force a plane to be grounded for several days. SAESL are currently working on developing a comprehensive On-Wing Care service. These repairs are just as detailed and intensive as if the engine had been brought into the facility, but instead are done either on the tarmac at an airport, or in the carrier’s hanger. These repairs can drastically reduce the time a plane is grounded and SAESL have seen more and more business flow their way in terms of engine on-wing repairs. “Although we rely heavily on engines coming into the workshop to be repaired, we are now seeing a rising trend of carriers wanting repairs and servicing to take place while the engine is still attached to the wing. Of course, we have moved with this trend and now our dedicated, highly skilled engineers can work on the engine while still attached, greatly reducing standing time for the carrier,” cites Morris.

POWERING THE FUTURE

SAESL will soon be offering a service and repair capacity for Trent’s new 787 engines, the driving force behind the Boeing Dreamliner fleet. The real bonus of offering such a facility is that there is currently no company in Southeast Asia that offers this facility, making them the only choice for carriers. This would open up a whole new revenue stream for the company as the Dreamliner is touted to become the plane of future passenger travel, which many carriers are looking to buy into. With engines on the new aeroplanes becoming more and more sophisticated and greener, SAESL have been investing further funds to advance the facility to incorporate these new engine designs. “We have been seeing a trend with carriers looking to have greener, more fuel efficient engines, such as the XWB on their planes. We seem to repair the older engines more frequently, so I think investing in engine training for our engineers and new equipment will ensure that SEASL remains the number one choice for repair in Asia,” proclaims Morris.

Morris pays tribute to the working ethos of the company’s employees and believes that Singapore is the Asian hub for skilled workers and technically minded people: “We have been blessed with an abundance of highly skilled workers, who really bring innovation and new approaches to the industry. They really are one of the main reasons that SEASL has been so successful over the last few years.”

With a reputation for service excellence and a strongly established customer base, SAESL are well positioned in the Asia-Pacific region for continued growth through the reliable and effective repair, maintenance and overhaul of Rolls-Royce Trent engines. SAESL truly are committed to their mission of “Servicing the Best, by the Best”.