Responsible for almost 40 percent of the country’s public transport use, Australian buses and coaches stand out as a driver of positive change amidst the national push towards net zero.

AUSTRALIAN BUS AND COACH SPOTLIGHT

Across the world, buses have provided a reliable and crucial mode of transport for many years, promoting social inclusion and access to education, healthcare, and employment.

Predominantly consisting of school and public route services, Australia’s bus and coach industry is no different.

It has undergone significant consolidation over the past few decades, transitioning from being dominated by small, family-run companies to the national and multinational businesses we see today.

Characterised by longevity, the average Australian bus fleet’s lifespan is 25 years, which has necessitated a gradual approach in the transition towards low and zero-emission technologies to ensure economic viability and minimal disruption.

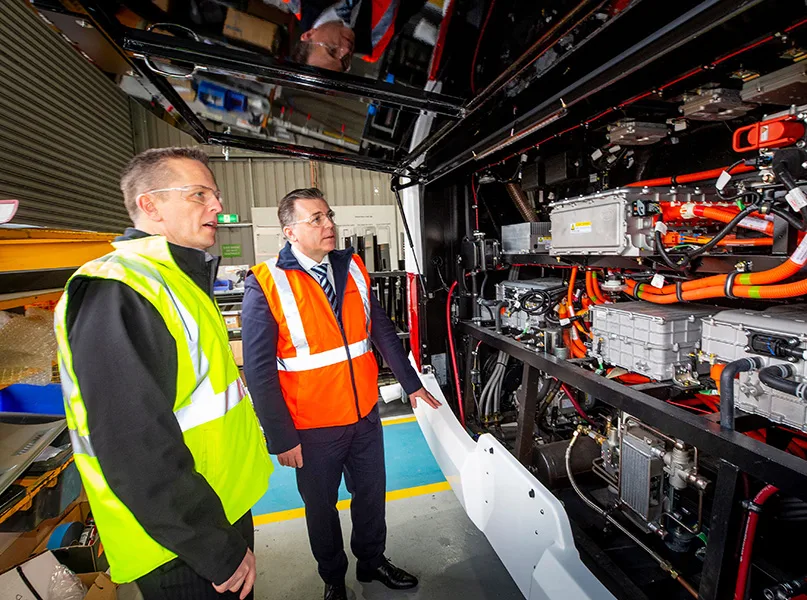

The bus and coach industry has so far been proactive in adopting various sustainable practices, steadily integrating technologies such as diesel-electric hybrids, battery and hydrogen-fuelled electric buses, and low-carbon liquid fuels (LCLFs).

This multifaceted approach helps address various operational needs and constraints, providing a robust pathway to zero emissions.

The industry also emphasises the importance of local manufacturing, supporting a viable Australian bus manufacturing sector to ensure the availability of jobs.

Additionally, workforce training and upskilling are critical to integrating emerging technologies and maintaining safety standards, whilst ensuring the accessibility and mobility needs of Australians have been identified as an equally important factor.

Overall, Australia is committed to a gradual transition towards net zero emissions across its bus fleets, implementing widespread infrastructure development and collaborating with the government on legislative policy to sustain this crucial industry.

Q&A WITH THE BUS INDUSTRY CONFEDERATION

Dean Moule, National Technical Manager, and Glen Bortolin, National Operations and Policy Manager at the Bus Industry Confederation, outline the organisation’s role in enacting change across Australia’s bus and coach sector and provide commentary on the increasing requirements for regulatory frameworks around safe bus design, configuration, operation, and maintenance

Firstly, could you outline the origins and primary goals of the Bus Industry Confederation?

Glen Bortolin, National Operations and Policy Manager (GB): Established 30 years ago, the Bus Industry Confederation (BIC) is a membership association for Australia’s bus and coach industry with around 160 diverse members, ranging from operators to manufacturers, suppliers, and associated service providers, who deliver direct and indirect goods and services to the industry.

We are a national peak body that advocates on behalf of the industry with the Commonwealth government, whilst we also have association members who oversee state-based advocacy and are made up of smaller bus operators.

Dean Moule, National Technical Manager (DM): Being a broad church in terms of our membership, we represent all sectors of the industry, from vehicle suppliers to components suppliers, service providers, or bus operators.

We see both sides of the coin in terms of bus supply and operation. Being based in Canberra, we deal regularly with the federal government on all things relative to the industry.

How extensively is BIC involved in contributing to and advising on government policy and legislation that may affect the Australian bus and coach industry?

DM: We are heavily involved at all levels of the federal space in terms of advocating for the needs of our industry.

Our supply comes from all over the globe, including the world’s biggest bus manufacturer, Yutong, in China, major European suppliers such as Irizar, Volvo, and Scania, and small, local Australian family businesses.

How do we advocate in this context? We are deeply involved in developing the Australian Design Rules (ADRs), which are national vehicle standards similar to the United Nations Economic Commission for Europe (UNECE) regulations.

In addition, we actively discuss the on-road operation of vehicles, which also assists us in overseeing manufacturing.

We are out there trying to create a diverse environment for our suppliers, from international importers to those that manufacture from the ground up in Australia, and we like to see that diversity remain because it provides a wide choice for our market.

Supporting local suppliers is a message that we need to continually push within the government because the Australian bus supply sector accounts for less than one percent of global supply.

We are also doing a lot of work around advocating for disability standards across the sector.

Meanwhile, as the bus industry comes under the same legislation as heavy vehicles, one of our challenges is making sure we remain distinct.

This becomes particularly important when we consider the way the heavy vehicle industry is taking the lead in the transition towards net zero, even though our manufacturers, suppliers, and importers have been building zero-emission buses for some time.

BIC is actively involved in various committees to ensure the government recognises the progress the bus and coach industry has already made towards achieving zero emissions.

We support the upskilling of existing staff, and we want to ensure the rules the government brings in around regulating electric vehicles (EVs) in the sector support what we have already put in place in terms of prioritising safety and positively impacting the environment.

Could you talk us through your recent developments in decarbonisation? What are your hopes for a more sustainable transport future for Australia?

DM: Most state governments in Australia have made announcements on the future purchasing of zero-emission public transport, primarily EVs, and are agnostic to the technology being used, whether it be hydrogen or fuel cell-powered electric buses.

We are trying to assist in this policy space, but one of the challenges we have faced is that the transition to net zero is expensive. We have seen some jurisdictions extending the life of their existing vehicles and prolonging the fleet’s lifespan to help offset the upfront capital cost of purchasing a new zero-emission EV.

However, this has created problems for manufacturers. It is a lot easier for all suppliers to be sustained when there are fewer peaks and troughs, and extending the life of vehicles in this way can be challenging because it creates an ‘order drought’, making it difficult for suppliers to justify viability.

Therefore, something we are strongly advocating for is long-term volume planning to sustain local manufacturing.

Currently, our sector employs 10,000 people directly and indirectly in the supply of vehicles to Australia – whether that is importing, manufacturing, or assembling. That is an AUD$5billion dollar contribution to the economy, which we want to sustain.

The other challenge we face is with the bespoke nature of bus supply. Currently, each vehicle is hand-built and tailored towards customers’ unique specifications, which means redesigning the same piece of gear multiple times to address these various requirements.

This will present a major obstacle as the industry seeks to build more harmonised products on a national scale. We support harmonisation as it brings down supply costs and increases quality, sustaining the future of the industry.

In terms of environmental sustainability, many of our organisations are already engaged in practices such as utilising battery energy storage systems (BESS) for EVs. The government is beginning to see this progress and acknowledges how the bus industry supports a green future.

The other challenge we face in the transition to net zero is competing on a global scale. As I said, we are a small part of a global footprint, but we also have leading suppliers here who build world-class products, some of which have been in the past, exported overseas to the United Arab Emirates (UAE), Singapore, and New Zealand.We would like to see this continue, but the high cost of competing on a global scale is a key consideration for the government. This can be challenging as you have one arm of the government concerned with value for money and the other looking to retain local jobs – the two do not necessarily see eye to eye.

“We support national harmonisation as it brings down supply costs and increases quality, sustaining the future of the industry”

Dean Moule, National Technical Manager, Bus Industry Confederation

How have you seen the Australian transportation industry evolve over the years?

DM: From a manufacturing perspective, since I began in the industry 39 years ago, I have seen it transition from a series of many smaller family businesses and evolve into something that is on a more sustainable, national scale.

At the same time, we are also seeing globalisation take hold. 20 years ago, I would say 95 percent of Australia’s vehicles were manufactured in the country, whereas now it is only around 65 percent. Again, that is fine in terms of diversifying our supplier base, but it does mean our products are now not only competing nationally but globally, which is challenging.

In this regard, we have policies in place to support local industry and address the challenges it faces. Australia’s various states and territories also have different policies on what is needed to meet local (state) content requirements, retain local (state) jobs, and keep suppliers and businesses running. This is challenging for any supplier to manage.

Currently, these policies are not harmonised nationally, so we are supporting the development of a strong Australian industry with harmonisation at multiple levels of the supply chain, all the way down to vehicle specifications and how local content is viewed.

Are you optimistic about the future of Australia’s transportation sector? What are BIC’s goals for the future and beyond?

DM: We are looking to ensure that we have better long-term volume planning for vehicle purchases across the country.

As such, we are aiming to harmonise state government purchases to assist our suppliers, manufacturers, assemblers, and importers to a greater extent by providing volume certainty and enabling them to look five steps ahead rather than one, in addition to improving economies of scale to support job creation.

Over time, we think harmonisation will involve having one central site producing better outcomes rather than lots of microsites, which may not be easy to begin with but will achieve longer-term sustainability for the industry.

GB: Another thing we want to see is a future where people opt to use buses rather than cars – building fewer roads but putting more buses on them.

Buses are the silent workhorse of the industry; every time a train or tram so much as sneezes, bus replacement services come in to save the day. Buses provide a more cost-effective, long-term, reliable, and flexible solution for the industry than any other mode of public transport. For this reason, we account for almost 40 percent of the country’s public transport usage.

Trains can only travel on a track, but buses can transport anyone, anywhere. This is why we think it is a superior mode of transport, and encouraging a widespread shift towards buses as the preferred mode of public transport is what we’re striving for.

Finally, what initiatives do you have in place to safeguard the future of the industry, from addressing skill shortages to integrating sustainability?

GB: We have just launched a retention and recruitment project to address how we should not only recruit new bus drivers but retain existing ones. We are seeking younger people and gender diversity as we want to get more female drivers into the industry.

However, due to the anti-social behaviour that our bus drivers can unfortunately sometimes experience onboard, we are grappling with how to achieve this.

DM: We are looking to attract people across various roles, from bus drivers to mechanics and electricians. It is all about making the bus industry a destination career choice, not just something that people fall into.

Moreover, the industry today has changed from 20 years ago as most of our time is now spent with computers, which attracts more employees.

Diversity is certainly important across all levels. We want to recruit as many genders, cultures, and identities to our industry as possible because the consequential benefits of having a more diverse workforce will allow us to grow organically.

Elsewhere, we are navigating the smooth transition towards more sustainable technologies, renewable fuels, and low-carbon liquid fuels. We are dedicated to finding the right technology solutions for the right application, which is reflected in our net zero policy.