We speak to Bernie Quinn, Engineering Director and Partner at Premcar Pty Ltd, about how the company is helping global carmakers and their Australian importers create new cars that buyers really want.

ENGINEERED, ENHANCED, ELECTRIFIED

“When the three big brands – Ford, GM-Holden, and Toyota – stopped assembling cars in Australia, there was a public belief the car industry in the country had died. This wasn’t true.”

The opening statement of Bernie Quinn, Engineering Director and Partner at Premcar Pty Ltd (Premcar), reflects the reality of how many of the companies underpinning the Australian automotive industry have continued to grow with new car engineering and manufacturing.

In the case of Premcar, an Australian engineering services provider and new-vehicle secondary manufacturer, the company has not only continued despite the disappearance of traditional big car brands but has experienced exponential growth unlike anything seen before.

“All of this is evidence that Australian car-making never died. At Premcar, we transferred our deep experience and skills into the next evolution of car manufacturing in Australia,” confirms Quinn.

Today, major carmakers of all sizes commission the company for almost everything. From developing entire new-vehicle platforms to enhancing a model series for a new buying audience to tuning a new car model’s steering and handling, Premcar does it all.

Premcar’s tagline – “Engineered. Enhanced. Electrified.” – aptly summarises what global automakers have come to rely on the company for.

Based in Epping, Australia, Premcar has been in business for nearly three decades and has proven its reliability and deliverance of high-quality services and products through consistent evolution and an innovative mindset.

Having been an engineer for 28 years, 20 of them spent at Premcar, Quinn has always held an inexhaustible passion for cars.

“Everything I did in my earlier years enabled me towards working with cars, so it was natural for me to pursue an engineering degree to participate in an industry that I’ve been obsessed with my entire life,” he excites.

Invigoration and unstoppable enthusiasm are ingrained within the core structure of Premcar and are evident in everything the company provides to its vast clientele.

AN AUSTRALIAN MANUFACTURING RENAISSANCE

“We’re seeing a renaissance of manufacturing in Australia, especially in the car industry. In the case of Premcar, this change has been customer-driven,” explains Quinn.

Australian automotive consumers have been the centrepiece of Premcar’s mission since its inception. With buyers walking into new car dealerships wanting vehicles that satisfy their particular needs and wants, it is critical for companies to meet these expectations and provide high-quality, exceptional cars.

As a prime example, high-performance AMG models have accounted for as much as 30 percent of total annual new car sales for Mercedes-Benz in Australia.

“Everyone at Premcar understands why; as the company behind Ford Performance Vehicles (FPV) for many years, Australian buyers want something special,” comments Quinn.

Premcar offers exactly that to its customers: something special.

One of the biggest differentiating factors when comparing Premcar to the competition is how the company puts its customers at the centre of every decision made, through its triad of business, product development, and manufacturing processes.

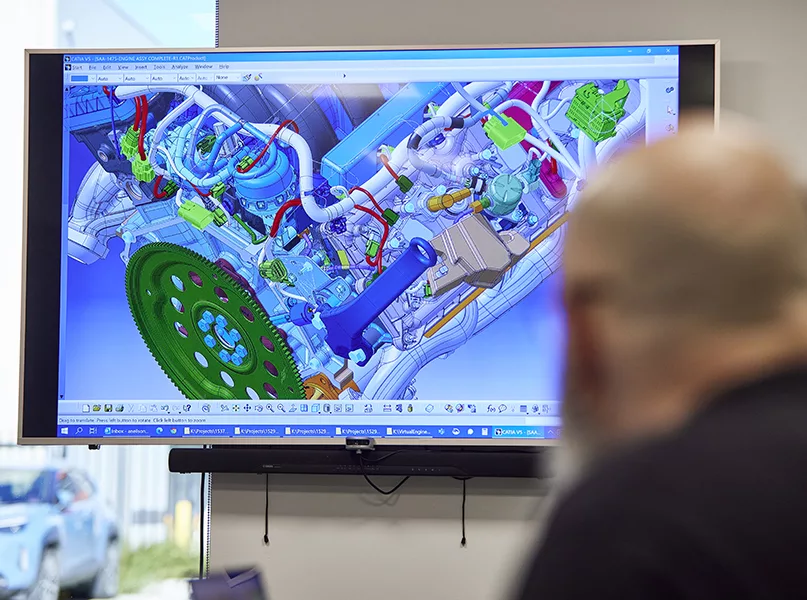

“We’ve built all three of these with the original equipment manufacturer (OEM) carmaker, and their customers in mind. This is why we use our own proprietary product development system, which we created to accurately fit our manufacturing process,” specifies Quinn.

Additionally, Premcar uses a systems and design-led approach when engineering and enhancing new cars. Doing this means that customers receive the new vehicle they want, which is of the utmost importance as ‘Made in Australia’ is a big drawcard for new car buyers in the country.

“Ultimately, our attention to detail and understanding of what our customers need makes us a company of choice. The new cars we create all have this understanding built into them, which explains why they’re so popular with buyers – it’s what we’ve been doing for 27 years,” confirms Quinn.

FROM SKETCH TO SHOWROOM

Working primarily with large global car manufacturers such as Nissan, Toyota, Ford, and Mazda, Premcar highlights the importance of partner-supplier relationships and how they contribute to the company’s success.

“We have great connections with our suppliers because we foster mutually respectful relationships; we don’t approach these commercial arrangements with a typical customer-supplier attitude,” notes Quinn.

“We take a relationship approach and always keep a long-term view. We thoroughly believe that openness and fairness are the best ways for everyone to benefit from these relationships,” he continues.

This effort to form strong, long-term connections with suppliers results in unparalleled quality and service that is tailored to the Australian market, allowing manufacturers and consumers alike to feel confident in their purchase.

Additionally, Premcar, along with its Australian supplier network, which includes SKF for specific bearing products and Tenneco for springs and dampers, collectively employs thousands of people in the local car industry, contributing to the overall longevity of this critical market.

“With some of our suppliers having been with us for more than two decades, we know that when a new-model vehicle is about to be released to the market, we can rely on them to be on-site and agile to help ensure every final check is met according to quality, time, and cost,” comments Quinn.

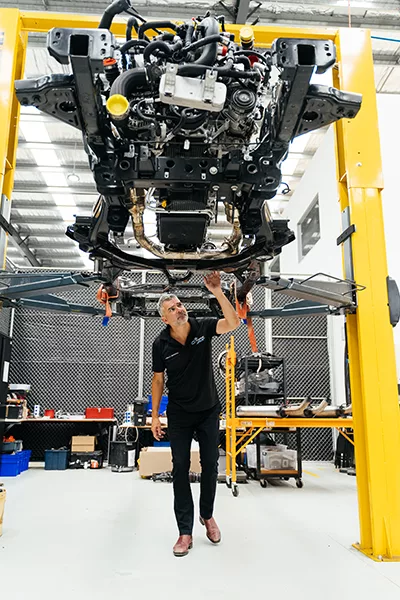

One such example of a successful release is Premcar’s recent Nissan Patrol WARRIOR, a world-class, full-size 4×4 SUV.

Retaining all of Nissan’s famed luxury, versatility, and quality, the WARRIOR was developed in Australia with local engineers using locally developed components that make it perfectly suited to Australian roads and terrain.

A major part of the WARRIOR’s success is due to it being engineered like that of an OEM-level new vehicle. All of the locally developed components and systems were fully integrated to work together with the vehicle, meaning that it operates as if the carmaker themselves created it.

“The WARRIOR is a great story about the depth of Australian engineering know-how and the quality of our local manufacturing. Believe me, you need both to create a vehicle like this,” prides Quinn.

Meeting and exceeding the necessary high standards for design, engineering, and manufacturing is what Premcar prides itself on, ensuring that innovation and customer-centricity are always at the forefront of the company’s priorities.

“The big car brands might have stopped assembling cars in Australia, but Australian buyers haven’t lost their desire for ‘Made in Australia’. car-making is alive and well”

Bernie Quinn, Engineering Director and Partner, Premcar Pty Ltd

A CUSTOMER-DRIVEN CHANGE

With a vast majority of new car buyers wanting vehicle choices that are tailored, special, and fit for a particular purpose, Premcar is not only meeting these expectations but surpassing them.

A commonly expressed desire that is continuing to increase in popularity is that of electric vehicles (EVs).

“New car propulsion systems are changing. Battery-electric vehicles (BEVs), for example, are quickly becoming mainstream, and EV technologies are crossing different vehicle classes. We are keeping pace with these changes and the many others being brought to the car-making world,” expands Quinn.

Premcar locally developed its first EV back in 2009 when it converted an Australian Ford Territory SUV to full battery-electric power. It has remained close to EV developments ever since.

The company has gone on to complete different EV projects for automakers, such as complete platforms for new EV model ranges and new car EV conversions.

“We are very well-versed in EVs. We’ve got the right skills and knowledge to create zero-emission vehicles to global OEM car-making standards,” confirms Quinn.

With the company’s engineering skills and experience, Premcar is actively contributing to the greater global need for cleaner transport.

Additionally, the company takes its corporate social responsibility practices seriously by participating in the annual R U OK? Day, offering mental health awareness sessions with external providers, and even hosting on-site massages for its staff.

“It’s all about making people aware of the importance of not only their own personal well-being, but the well-being of others around them, and even people outside of the company,” explains Quinn.

Continuing to manage the significant growth the company has been creating in a healthy and sustainable manner is a key priority for Premcar in the upcoming years.

As demand increases for new cars developed and manufactured in Australia, employee numbers at Premcar will continue to grow. By the end of 2023, the company will have expanded its revenue by approximately 50 percent.

“We’ve experienced a lot of business expansion in the last 10 years, and we pride ourselves on being a large Australian car industry employer and player,” concludes Quinn.

The future is tremendously exciting for Premcar. Being in such a dynamic and constantly evolving industry, the potential is endless.