Providing Australian industry access to excellent test measurement and analysis tools, EngAnalysis has recently turned its attention to the needs of the nation’s mining sector. Engineering Manager, John Vazey, tells us more.

UNLOCKING EFFICIENCY, ENABLING PRODUCTIVITY

Founded in 2015, EngAnalysis is an Australian engineering and technology consultancy that seeks to enable its clients to make decisions informed by science, engineering, and measurement.

“Our overall approach allows us to address critical issues with the design, performance, structural capacity, and operation of clients’ major engineering assets,” introduces John Vazey, Engineering Manager at EngAnalysis.

Most recently, the company has been focusing on unlocking efficiency and productivity in the mining sector, primarily by providing real-time structural health monitoring.

As such, it has used sensors and analytics software for troubleshooting, design verification, and assessing the risks of potential safety hazards in local mines.

This innovation has arisen in response to the Australian mining and mineral processing industries facing complex challenges, putting workers, equipment, operations, and the environment at risk.

“The effective planning and design of machinery, structures, and processes not only helps to mitigate these risks but drives improved operational performance,” Vazey enthuses.

Therefore, EngAnalysis’ early identification of potential safety hazards or design flaws in mines through real-time monitoring and computational analysis of a prototype seeks to considerably improve performance, safety, and operations.

“This process also minimises downtime by reducing the potential for equipment failure,” he adds.

ANALYSING DATA TO ENABLE EFFICIENCY

Having evolved into Australia’s leading industrial testing and structural monitoring service provider, EngAnalysis delivers projects for some of the country’s most critical infrastructure.

Its highly qualified engineers and analysts provide EngAnalysis with real-time, in-depth data analysis and interpretation from a wide range of measurement, verification, and assessment methods.

“These include mechanical, thermofluid, and structural design, analysis, validation, and verification, so our clients can confidently make informed decisions,” Vazey details.

The company’s verification, validation, and correlation of designs through computational simulations and focused data acquisitions can help to optimise mines.

“We also work to reduce over-engineering and minimise unnecessary expenses from a procurement and maintenance perspective,” he continues.

EngAnalysis’ approach aligns closely with the findings of a recent McKinsey report, which emphasises the implementation of sensors and machine learning (ML) in mines to enable improved efficiency, productivity, and sustainability.

“Our overall approach allows us to address critical issues with the design, performance, structural capacity, and operation of clients’ major engineering assets”

John Vazey, Engineering Manager, EngAnalysis

ENHANCING PRODUCTIVITY IN AUSTRALIAN MINES

Recently, Vazey and the EngAnalysis team undertook a local project in which a mine was experiencing faults in critical machinery at its processing plant, resulting in operational delays and unplanned downtime.

To address the issue, EngAnalysis surmised that it needed to address the root cause of the machinery failure and devise an effective repair plan that could be closely monitored.

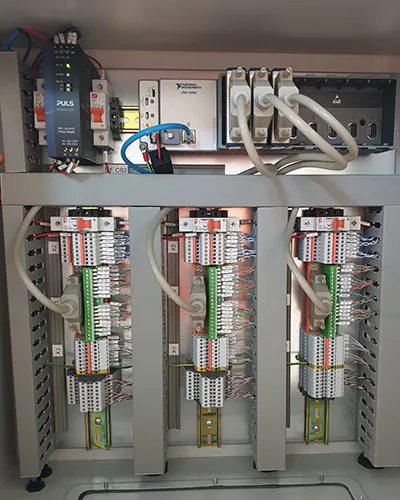

In this way, Vazey and the team developed a monitoring system for the machinery, which utilised specialised software to record structural stresses and identify operational cycles.

“We were able to immediately analyse the data for potential issues such as overloading or uneven loading.”

The company also developed metrics on the machinery’s performance, fatigue, and deterioration, which enabled engineers to track data trends and determine when intervention might be necessary.

“With our insight, mine operators will be able to halt operations to adjust the load on equipment, preventing structural failures and potentially lengthy periods of downtime,” he reveals.

INFORMED INNOVATION

Eventually, a new machinery design for the mine was devised, informed by the data collected by EngAnalysis.

The new machinery included strain gauges and measurement tools to monitor its performance over a set period of time.

The data gathered was then used to conduct a fatigue assessment and predict the equipment’s overall operational lifespan.

“The strain measurements in this process enabled us to characterise the process behaviours that had originally led to failures and unwanted downtime,” Vazey asserts.

Therefore, EngAnalysis has been able to provide the mining industry with the confidence that new equipment designs will have an adequate lifespan.

“In the long term, this will enhance a mine’s overall productivity and reduce maintenance costs,” he concludes.