As the world’s largest and most experienced supplier of grinding media, Jim Anderson, CEO of Molycop, discusses how the company’s continued investment in research, development, and advanced technology delivers improved outcomes to customers.

THE FUTURE OF MINING

With over a 100-year history built on reliable innovation and a conscious global footprint, Molycop is a time-tested, world-leading partner for consumable products, instrumentation, and services for the global mining industry and rail and manufacturing sectors in Australia.

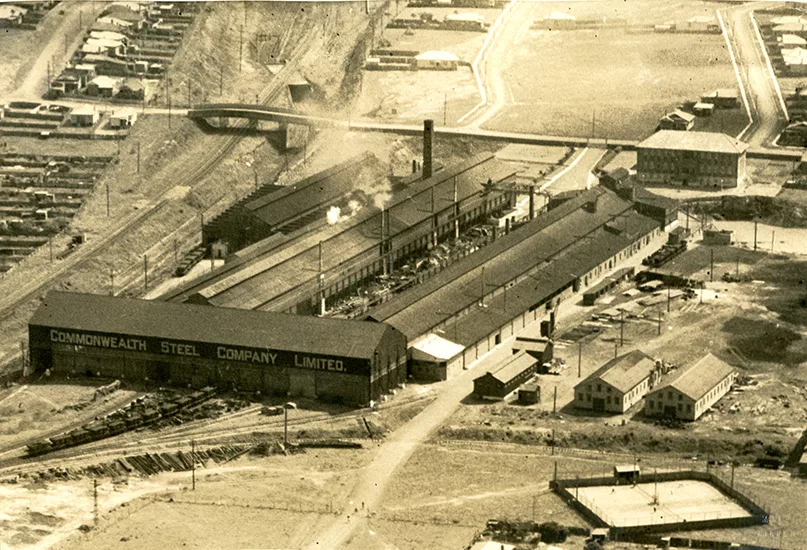

With origins tracing back to the Australia-based Commonwealth Steel and US-based Sheffield Steel businesses, both of which independently developed grinding media products for minerals processing, Molycop prides itself on providing innovative and high-quality products, world-class technical support, and delivering outstanding supply assurance.

“We’re incredibly proud that Molycop’s strength is not one or two things in isolation; it is the sum of our parts,” opens Jim Anderson, CEO of Molycop.

“We are focused on helping our customers increase throughput and maximise recovery with our portfolio of products and services across milling, flotation, leaching, process optimisation, and training.”

Coming from a rich and deep history of serving the world’s copper and gold mining segments, Molycop now operates a global business model with over 1,500 dedicated employees who service over 400 mines across 40 countries, being the largest grinding media supplier in the world.

With major operations in Chile, Peru, Mexico, the US, Canada, Australia, Indonesia, and Spain, Molycop leverages the full talent of its network to provide the best solutions for customers with a unique local nuance and expertise.

AT THE CUTTING EDGE OF INNOVATION

“Innovation is in Molycop’s DNA.”

Being able to call yourself an industry leader is no small feat; Molycop has been able to set these standards and differentiate itself as a result of its investments in research and development (R&D) and the people who work hard to make results happen – whether it be by upskilling or attracting the industry’s brightest minds.

In addition, Molycop has partnered with some of the world’s leading universities, acquiring a competitive edge when it comes to developing and retaining people, ensuring that they are well-equipped for the future.

“Importantly, the way we collaborate with our customers and stakeholders also drives this progress,” clarifies Anderson.

The innovation strategies Molycop provides aim to yield fast, credible solutions to the social and fiscal challenges that customers face. These strategies also enable the sustainable liberation of resources essential for a better tomorrow.

“Together we are able to solve the big challenges our industries face, setting new benchmarks, evolving to market trends, and ultimately delivering improved outcomes for our customers,” notes Anderson.

The future of mining, like that of any industry, is always changing, and Molycop is all about ensuring the change is for the better. By playing our part in the transformation of the mining sector and improving the ways in which everyday things get done, Molycop is always aspiring to be innovative and ahead of the curve, with a constant focus on forward momentum.

“Our unique selling point is one that places us beyond direct comparison. We’re incredibly proud that Molycop’s strength is not one or two things in isolation; it is the sum of our parts”

Jim Anderson, CEO of Molycop

PROCESS OPTIMISATION SOLUTIONS

As is expected in any major industry that plays a large part in driving economic growth, the mining industry is continually evolving and facing new challenges, including pertinent subjects such as declining head grades, skillset challenges, and developing local communities.

However, technology is an enabler that allows the industry to meet these challenges head-on.

“Molycop has been the leader in our industry for over 100 years, and it’s only a natural progression and is expected we take a leadership position in working with our customers to help them solve these issues through the use of more advanced technology,” comments Anderson.

Operating with the desire for constant evolution and standing at the forefront of the industry, Molycop has established a new business portfolio under the strength and reputation of the company brand to emphasise its commitment to sustainability and innovation with the extensive range of products and services at the customer’s disposal.

For example, Molycop’s innovation team has significant research projects underway with leading universities in materials science and comminution. With a major initiative such as the development of the Molycop Digital Engine, projects such as these underpin the future product and service developments within the company.

“These new capabilities truly build on Molycop’s rich history, paving the way for a future that’s better when we create it together,” expands Anderson.

Under one strong identity, Molycop prides itself on its holistic portfolio offered to customers, continuously raising the bar for progress, accessibility, and reliability.

ARTIFICIAL INTELLIGENCE AND MACHINE LEARNING

Molycop has placed a focus on moving beyond the accuracy and flexibility limitations of traditional mineral processing analytical techniques, which were traditionally based on empirical models and rule-based systems, to opportunities in new powerful tools for data analysis, prediction, and optimisation.

“Around the world, we are seeing a positive impact in the way Molycop’s customers are benefitting from artificial intelligence (AI) and machine learning (ML),” notes Anderson, “including real-time predictions and the optimisation of mineral processing operations.”

One such example of this positive impact that has been developed to predict the behaviour and optimise the performance of comminution circuits is the Molycop Digital Engine, an advanced intelligence computational framework specifically tailored for optimising crusher-to-floatation circuits. Additionally, the Digital Engine is integrated with Molycop’s mill monitoring system, including shell and mill sensor data with main operating variables.

Always leading the way for progress and innovation, Molycop’s Dr. Yousef Mohammadi will present a paper, eMolycop Digital Engine: Machine Learning-accelerated SAG Mill Optimisation, at SAG 2023 in Vancouver. And Mukesh Singh Bisht, who is undertaking his PhD co-supervised by Molycop at Sydney University, will present a poster display titled “Heterarchical Comminution Model for Rotary Mills”.

Advanced instrumentation, data capture and visualisation, and data integration with AI and advanced analytics overlay are all aspects that are crucial to the future of mining and are supported by Molycop’s global team of qualified experts.

GLOBAL SUSTAINABILITY

As a company with an expansive global reach, Molycop works to positively impact people, support local communities, and minimise our environmental footprint through every aspect of the company.

Committed to the pursuit of greater sustainability in a manner that allows for superior efficiency of resources and achieves the highest standard of environmental performance, Molycop is dedicated to creating lasting benefits that are responsible, transparent, and respectful to the rights of all.

Polymer Injection Technology (PIT) is a groundbreaking initiative Molycop, in collaboration with the University of New South Wales (UNSW), is spearheading to reshape Electric Arc Furnace (EAF) steel manufacturing by partially substituting traditional coke with rubber from tyres and other sources.

“The benefits are many; however, the clear environmental stewardship is a focus area for us. Beyond financial advantages, PIT significantly reduces carbon emissions by minimising electrical energy consumption,” expands Anderson.

Additionally, Molycop has developed a sustainability strategy to articulate priorities, provide clear actions to meet objectives and enable the monitorisation of progress against agreed targets.

This strategy includes three strategic pillars: “doing better for the future, with a focus on environmental material topics; doing what matters, ensuring our social works and people focus is maintained; and doing what’s right, managing our organisation with strong ethics and governance arrangements,” explains Anderson.

Molycop also has a critical role to play in helping the industry deliver the copper it needs for a low-carbon future, as the demand for copper used for solar and wind is forecast to double by 2035. In doing this, Molycop is focusing on delivering consumable products that have increased wear life and are optimised for varying mill operating conditions – increasing the throughput and recovery in the comminution process.

With the belief that one of the best ways to promote sustainable development is to innovate new and better technologies and to change current ways of operating, the focus is always on the future at Molycop, taking the responsibility of providing for customers very seriously.